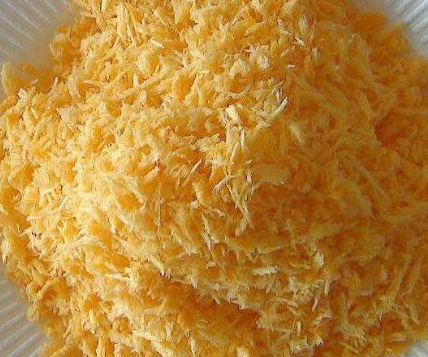

Beyond the Crunch: A Guide to Bread Crumb Varieties

Breadcrumbs are a pantry staple that transcend cultures and cuisines. Far more than just a filler or coating, the right type of breadcrumb can define a dish’s texture, flavor, and appearance. bread crumb machine for sale From the lightest crisp to a hearty crust, here is a guide to the world of bread crumb varieties. I. By Texture & Form: The Structural Foundation This is the most fundamental way to categorize breadcrumbs, determined by the size of the crumb and its intended use. II. By Bread Type: The Flavor Dimension The flavor of the original bread profoundly impacts the final dish. III. By Preparation & Seasoning: The Ready-Made Spectrum Choosing […]

The Hidden Catch: A Look Inside the Industrial Fish feed Machine

The global aquaculture industry, which now supplies over half of the world’s seafood, is powered by a single, critical input: formulated feed.fish food making machine For farmed salmon, shrimp, tilapia, and seabass, the pellets they are fed are not simple ground-up fish. They are the product of sophisticated, industrial-scale engineering designed to optimize growth, control cost, and manage environmental impact. Here’s what happens inside the aquafeed factory. 1. The Raw Material Paradox: Saving the Oceans by Using Them Differently The core challenge of modern aquafeed is replacing the historical cornerstone: wild-caught fishmeal and fish oil. Early feeds relied heavily on these ingredients, leading to criticism of “fishing down the food […]

The Twin-Screw Extruder: Engineering the Modern Food Revolution

In the heart of countless industrial plants—from pet food factories to cereal mills and plant-based protein labs—hums a machine of remarkable versatility and precision: the twin-screw extruder. Far more than a simple cooker, it is a sophisticated, continuous chemical and mechanical reactor that extruder machine transforms raw powders and pastes into a vast array of finished products. This is the workhorse behind the shape, texture, and nutrition of modern processed foods. Core Principle and Design At its essence, a twin-screw extruder is a barrel housing two intermeshing, co-rotating or counter-rotating screws mounted on parallel shafts.extruder machine This twin-screw design is its key advantage over older single-screw machines, offering superior control, […]

The Illusion of Choice: What Really Goes Into Commercial Dog Food

Walk down any pet store aisle, and you’re bombarded with vibrant bags featuring plump chickens, fresh-caught salmon, and garden-fresh vegetables.dog food making machine The marketing promises “complete nutrition,” “wholesome ingredients,” and a “natural diet.” But behind this carefully crafted image lies a vastly different reality—an industrial process driven by cost-efficiency, rendering, and chemical alchemy. This is the truth about how most commercial kibble is made. Part 1: The Raw Materials: “Meal,” By-Products, and Renderers’ Gold The primary protein source in most kibble is not the succulent meat pictured on the bag. It is “meal.” Chicken meal, meat and bone meal, poultry by-product meal. These powdered ingredients are the cornerstone of […]

From Raw Ingredients to Nutritious Kibble: The Journey of Dry Dog Food

From Raw Ingredients to Nutritious Kibble: The Journey of Dry Dog Food The production of high-quality dog food is a sophisticated process that blends nutritional science with precision engineering. It transforms raw agricultural ingredients into the safe, stable, and nutritious kibble that fuels our canine companions. The most common type is dry kibble, produced through a method called extrusion. Here’s a step-by-step look at how it’s made. Stage 1: Formulation and Ingredient Sourcing It all begins with a recipe formulated by veterinary nutritionists and food scientists. This recipe ensures the final product meets specific nutritional standards, such as those set by the Association of American Feed Control Officials (AAFCO). Ingredients […]

Classification of Snack Foods: A Comprehensive Guide

Classification of Snack Foods: A Comprehensive Guide Snack foods represent a diverse and ever-evolving category of edible products consumed between traditional meals. The global snack food industry has expanded dramatically, offering consumers an endless array of choices. This article provides a systematic classification of snack foods based on various criteria including processing methods, primary ingredients, texture, and consumption patterns. 1. Classification by Processing Method a) Extruded Snacks b) Baked Snacks c) Fried Snacks d) Roasted Snacks e) Air-Puffed Snacks 2. Classification by Primary Ingredient a) Potato-Based Snacks b) Corn-Based Snacks c) Grain-Based Snacks d) Nut and Seed Snacks e) Fruit and Vegetable Snacks f) Protein-Based Snacks g) Seafood Snacks 3. […]

Unveiling the Secrets of Extruded Food Production: The Magic Behind the Crunch

Unveiling the Secrets of Extruded Food Production: The Magic Behind the Crunch Have you ever wondered how your favorite breakfast cereal gets its perfect O-shape, or how cheese puffs achieve their airy, melt-in-your-mouth texture? The answer lies in a remarkable industrial process called extrusion – one of the food industry’s most versatile and well-guarded manufacturing secrets. This article pulls back the curtain to reveal how raw ingredients are transformed into the familiar foods that fill our pantries. snacks machinery The Extrusion Machine: A Food Factory in a Tube At the heart of the process lies the extruder – a sophisticated piece of engineering that functions as a complete cooking and […]

Classification of Extruded Foods: From Snacks to Staples

Classification of Extruded Foods: From Snacks to Staples Extrusion is a versatile and efficient food processing technology that utilizes heat, pressure, and shear force to transform raw ingredients into a wide variety of products. By forcing a material through a die, extruders can shape, texture, cook, and mix in a single continuous operation. Extruded foods can be classified based on several key criteria, including processing conditions, final product characteristics, and intended use. 1. Classification by Process Temperature and Moisture This is the most fundamental way to categorize extruded foods, as it directly defines the product’s structure. a) High-Pressure/High-Temperature Extrusion (Expanded Foods) b) Low-Pressure/Low-Temperature Extrusion (Non-Expanded or Formed Foods) 2. Classification […]

The Manufacturing Process of Dry Cat Food: Precision Nutrition for Felines

The Manufacturing Process of Dry Cat Food: Precision Nutrition for Felines Dry cat food, or kibble, is a popular choice for pet owners due to its convenience, long shelf life, and nutritional completeness. The production process combines science and technology to create a balanced diet that meets the unique dietary needs of cats, which are obligate carnivores. This article outlines the key stages in the commercial manufacturing of extruded dry cat food. 1. Ingredient Selection and Formulation The process begins with careful ingredient selection tailored to feline biology. Cats require high levels of animal-based protein and specific nutrients like taurine, which is essential for their health. Common ingredients include: 2. […]

The Manufacturing Process of Dry Dog Food: From Raw Materials to Kibble

The Manufacturing Process of Dry Dog Food: From Raw Materials to Kibble Dry dog food, commonly known as kibble, is a popular pet food format due to its convenience, nutritional completeness, and long shelf life. Its production is a precise science that combines animal nutrition, food safety, and thermal processing to create a balanced and palatable diet. This article outlines the key stages in the commercial manufacturing of extruded dry dog food. 1. Ingredient Selection and Receiving The process begins with the selection and quality control of raw materials. Ingredients are chosen based on their nutritional profile, cost, and availability. Common components include: All incoming ingredients are inspected and tested […]

The Production Process of Fortified Rice: Enhancing Nutrition at Scale

The Production Process of Fortified Rice: Enhancing Nutrition at Scale Fortified rice is a powerful tool in the global effort to combat malnutrition. It is designed to look, taste, and cook like regular rice while providing essential vitamins and minerals that are often lacking in the diet. The production process involves coating or embedding nutrients into rice grains, creating a product that can significantly improve public health. This article outlines the primary methods used in the commercial production of fortified rice. 1. The Need for Fortification Rice is a staple food for over half of the world’s population, particularly in Asia, Africa, and Latin America. However, regular milled white rice […]

The Manufacturing Process of Breakfast Cereal: From Grain to Bowl

The Manufacturing Process of Breakfast Cereal: From Grain to Bowl Breakfast cereals are a popular morning meal known for their convenience, nutritional value, and variety. The production process transforms raw grains like corn, wheat, oats, or rice into the crispy, flavorful flakes, puffs, or shapes found in boxes. While specific methods vary by type (flaked, puffed, extruded), the general industrial process follows several key stages. This article outlines the primary steps in commercial breakfast cereal production. 1. Ingredient Selection and Preparation The main ingredient is whole grains or grain components (e.g., corn grits, oat flour). These are inspected and cleaned to remove impurities like dust, husks, or stones. Other ingredients […]