Beyond the Jar: A Clear-Eyed Look at How Baby Rice Cereal is Made

Infant rice cereal is often a baby’s first solid food, recommended for its mild taste, smooth texture, and easy digestibility. Yet, its manufacturing process is often shrouded in simplicity, baby food maker with marketing focusing on fortification and purity. This article unveils the standard industrial production process, highlighting both its engineered benefits and the considerations parents should be aware of. The Core Process: From Grain to Fine Powder The primary goal of manufacturing is to create a sterile, shelf-stable, and easily digestible powder that reconstitutes instantly with water, breast milk, or formula. 1. Sourcing & Cleaning:The process begins with white rice (often milled to remove the bran and germ). Brown […]

The Crumbling Bowl: An Analysis of the Cereal Market’s Shifting Landscape

For decades, the breakfast cereal aisle, dominated by iconic cornflake boxes, represented a pinnacle of food marketing and habitual consumption. how corn flakes are made However, the market’s once-sturdy foundation is now facing unprecedented erosion. A clear-eyed analysis reveals a sector navigating a complex transition, where legacy strengths are challenged by powerful, enduring consumer trends. The Legacy Strengths Under Pressure Traditionally, the cereal market thrived on: Today, each of these pillars is being critically re-examined. The Primary Headwinds Reshaping the Market 1. The Health & Wellness Revolution (The Core Challenge):Modern consumers, armed with information, are scrutinizing nutrition labels. how corn flakes are made The core critique is undeniable: many leading […]

How to Bake Your Own Corn Chips at Home

How to Bake Your Own Corn Chips at Home Making crispy, golden corn chips at home is a surprisingly simple and rewarding process. cereal flaking By baking instead of frying, you create a healthier snack that you can customize with your favorite seasonings. Here’s a step-by-step guide to perfect homemade baked corn chips. Why Bake Instead of Fry? Baking uses significantly less oil, resulting in a lighter chip with fewer calories. It also gives you complete control over the ingredients, cereal flaking allowing you to avoid preservatives, excess salt, and artificial flavors. The texture is delightfully crisp, and the corn flavor truly shines. Essential Ingredients & Tools Step-by-Step Baking Instructions […]

Unveiling the Assembly Line: The Engineered Journey of a Cornflake

For over a century, the simple, golden cornflake has been a breakfast table staple, symbolizing quick, wholesome nutrition. how are corn flakes madeBut its journey from a field of dense maize to the light, crispy flake in your bowl is anything but simple. It is a marvel of modern food engineering—a precise, multi-stage process designed for consistency, shelf stability, and that satisfying crunch. Let’s pull back the curtain on how cornflakes are truly made. 1. The Raw Material: Not Just Any Corn The process begins not with sweet corn, but with field corn (dent corn), chosen for its hardy endosperm and low moisture content. Kernels are first thoroughly cleaned, then […]

The Multifaceted Magic of Breadcrumbs: Your Kitchen’s Secret Weapon

Often overlooked in the pantry, breadcrumbs are a culinary chameleon, capable of far more than just coating a schnitzel. bread crumb coating machine From creating irresistible textures to rescuing dishes from disaster, their utility is vast. Here’s a comprehensive guide to the many roles breadcrumbs can play. 1. The Crispy Architect: Coating & Frying This is their most famous job. A standard breading procedure—first flour, then egg wash, then breadcrumbs—creates a protective, golden crust when pan-fried, deep-fried, or air-fried. 2. The Master Binder: Holding Things Together Inside mixtures, breadcrumbs absorb excess moisture and act as a glue. 3. The Flavorful Crown: Toppings & Gratins Mixed with butter, oil, herbs, and […]

Beyond Crunch: The Unsung Hero of Your Kitchen – Breadcrumbs

In the culinary world, some ingredients demand the spotlight, while others work their magic quietly behind the scenes. Breadcrumbs, those humble, golden-brown particles, firmly belong to the latter category. Far more than just a coating for fried chicken or fish, bread crumbing machinethey are a versatile powerhouse that can transform texture, enhance flavor, and solve common kitchen dilemmas with surprising elegance. 1. The Master of Texture: Coating and FryingThis is their most iconic role. A classic three-step dredge in flour, beaten egg, and breadcrumbs creates a magical barrier for pan-frying or deep-frying. The result? A shatteringly crisp, golden exterior that locks in the natural juices of proteins like chicken cutlets, […]

From Crust to Crunch: The Journey of Breadcrumbs

Breadcrumbs, known commercially as breading or “panko” in their Japanese form, are a staple ingredient found in kitchens and food processing plants worldwide. bread crumb coating machine Their journey from simple loaf to uniform crumb is a fascinating example of food engineering, blending tradition with industrial precision. The Raw Material: Selecting the Bread The process begins not with crumbs, but with whole bread. Manufacturers typically use one of three sources: The Core Production Process Stage 1: Drying & StabilizationFresh bread has about 35-40% moisture, which would cause crumbs to clump and spoil. The bread is therefore dried in large industrial ovens or belt dryers. The goal is to reduce moisture […]

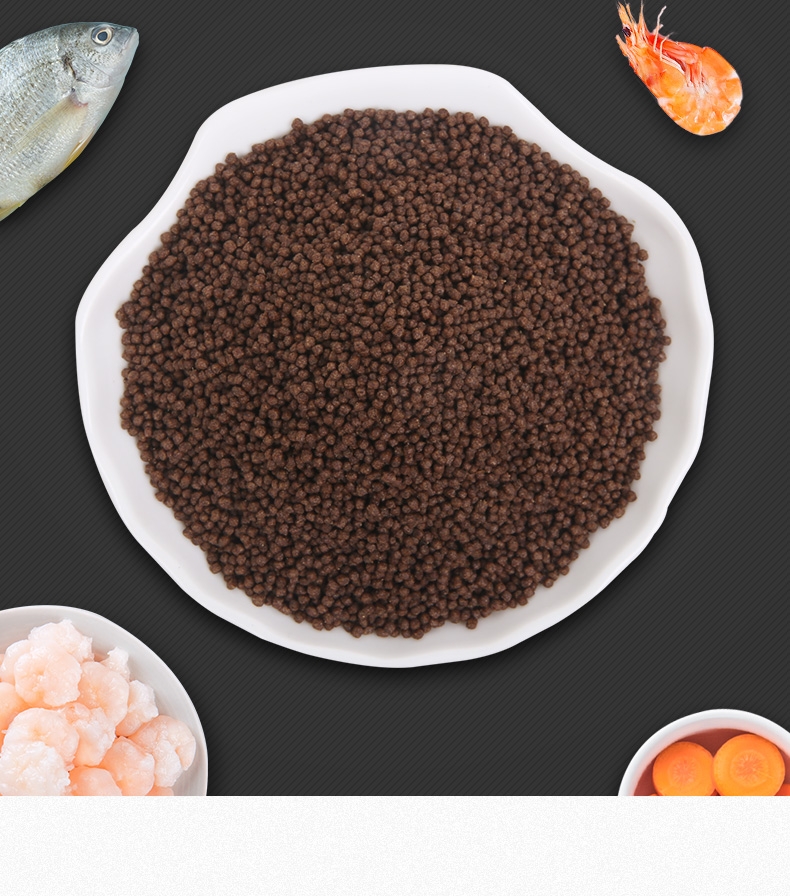

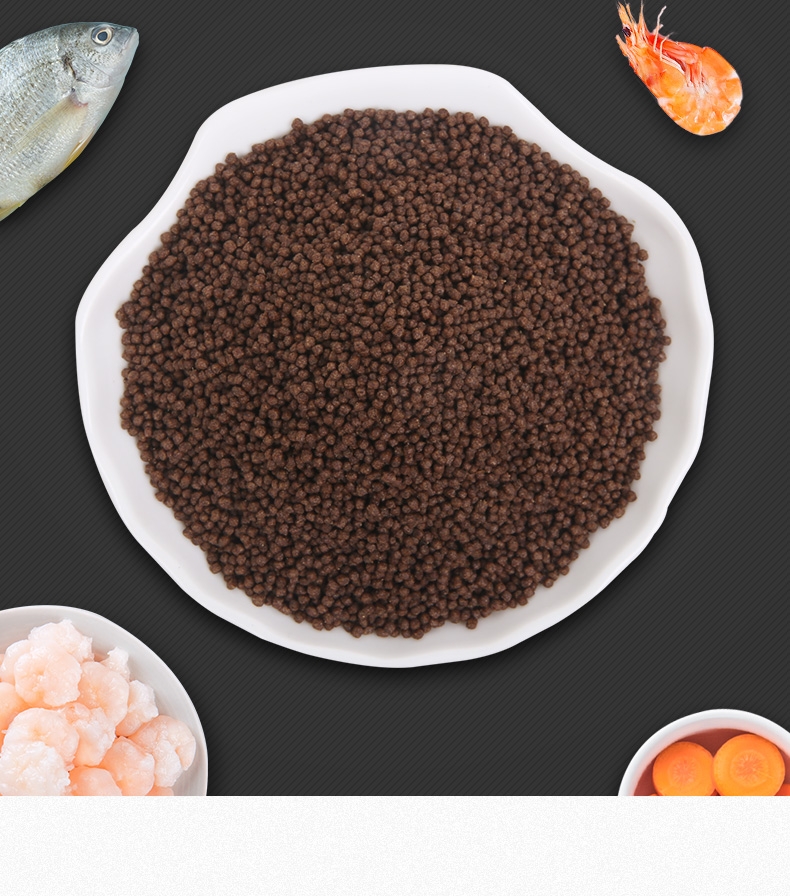

The Invisible Art: How Fish Feed Pellets Are Dried

In the fish feed manufacturing process, drying is the critical, yet often overlooked, stage that transforms soft, vulnerable pellets into stable, shelf-ready products. fish food pellet making machine It is a precise balance of heat, airflow, and time—a delicate operation where science meets industrial efficiency to ensure nutritional integrity and longevity. The Critical Role of Drying Freshly extruded (for floating feed) or pelleted (for sinking feed) pellets emerge hot and moist, with a moisture content of 23-30%. fish food pellet making machine This high moisture level makes them perfect breeding grounds for mold and bacteria, prone to clumping, and too soft for packaging and transport. The dryer’s mission is to […]

Surface vs. The Depths: Decoding the Key Differences Between Floating and Sinking Fish Feed

In the world of aquaculture and fish keeping, the choice between floating and sinking feed is not a matter of preference but of precision. fish food pellet machine These two fundamental types of feed are engineered for distinct purposes, targeting different species, farming systems, and management strategies. Understanding their differences is crucial for optimal fish health, growth, and operational efficiency. 1. Core Physical Property: Buoyancy & Manufacturing This is the most visible and foundational difference, driven entirely by the production process. 2. Primary Application & Target Species The choice is dictated by the natural feeding behavior of the fish. 3. Feeding Management & Monitoring This difference dramatically changes how a […]

The Submerged Sustenance: A Deep Dive into Sinking Fish Feed Pellets

While floating pellets dominate the surface, a parallel universe of nutrition exists below—the world of sinking fish feed. fish food manufacturing machines These dense, compact pellets are engineered to descend, catering to the fundamental needs of a vast array of aquatic species. More than just an alternative, they represent a critical, species-specific feeding strategy grounded in biology and precision. The Core Engineering: Density by Design Unlike their buoyant counterparts, sinking pellets are manufactured to be denser than water. This is primarily achieved through one of two methods: Key Characteristics & Biological Advantages The Formulation Profile Sinking feed formulations are tailored to the target species but share common traits: Considerations and […]

The Unsinkable Meal: A Close Look at Floating Fish Feed

In the world of aquaculture and ornamental fish keeping, floating fish feed pellets are a ubiquitous sight. These buoyant, fish food making machine price uniform nuggets bobbing on the water’s surface are more than just convenient—they are the result of sophisticated food engineering designed to maximize efficiency, observation, and health. Let’s dive into what makes this feed float and why it’s so widely used. The Core Principle: Density Defiance At its heart, a floating pellet defies a simple law: it is less dense than water. This is achieved not by magic, but by physics during the manufacturing process known as extrusion. During extrusion, the starch-rich ingredient mix (containing grains like […]

The Secret Life of a Pellets: Demystifying How Fish Feed is Formed

That perfectly uniform, sinking or floating pellet you sprinkle into your aquarium or that is dispensed by the ton into salmon pens is not a simple dried nugget of ground-up fish. fish food machine automatic It is the result of sophisticated food engineering, a process designed to balance nutrition, water stability, and manufacturing efficiency. Let’s pull back the curtain on the factory floor to see how fish feed gets its shape. Stage 1: The Raw Powder Blend – The “Dry Mix” It all begins with a homogenous powder. This mix is a precise recipe formulated by aquaculture nutritionists and can include: This dry blend is thoroughly mixed in giant industrial […]