Needle-shaped breadcrumbs—often marketed as panko or “Japanese-style breadcrumbs”—are widely praised for their light texture, crispy bite, and superior frying performance. bread crumbs machine price They are commonly used in fast food, frozen products, and industrial catering. However, behind their clean appearance and appealing crunch lies a highly industrialized processing method that is rarely disclosed to consumers.

What Are Needle-Shaped Breadcrumbs?

Unlike traditional breadcrumbs, which are made by grinding dried bread, needle-shaped breadcrumbs are engineered products. Their elongated, porous structure does not occur naturally through simple crushing. Instead, it is the result of a controlled manufacturing process designed to optimize texture, oil absorption, and shelf stability.

Step 1: Highly Refined Raw Materials

The process typically begins with refined wheat flour, often with low ash content and minimal fiber. Nutritional components naturally present in whole grains—such as bran and micronutrients—are largely removed at this stage. bread crumbs machine price To standardize performance, manufacturers frequently add:

- Vital wheat gluten (to improve elasticity)

- Sugar or glucose syrup (to promote browning)

- Emulsifiers and dough conditioners

- Yeast or chemical leavening agents

The goal is not flavor or nutrition, but structural consistency.

Step 2: Specialized Dough and Controlled Fermentation

The dough is mixed to a precise hydration level, producing a soft and extensible mass. Fermentation, if used at all, is often shortened or tightly controlled. In many industrial settings, chemical leavening partially replaces traditional yeast fermentation to reduce time and cost ⏱️.

This results in bread that looks like bread—but behaves more like a semi-synthetic base material.

Step 3: Electrical or Mold Baking Technology

One of the least discussed stages is the baking method. Instead of conventional ovens, many manufacturers use electrical baking systems or mold baking:

- Dough is baked without crust formation

- Heat is applied internally, not from the surface

- Moisture distribution is artificially controlled

This prevents browning and creates a spongy, white loaf with large, uniform air cells—ideal for later shredding.

Step 4: Mechanical Shredding into “Needles”

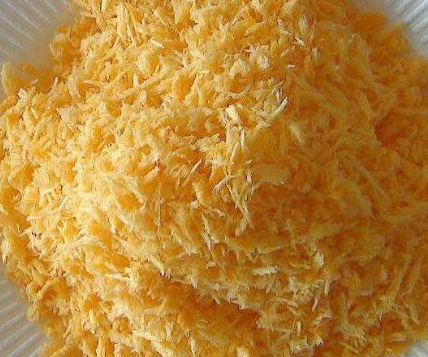

After baking and cooling, the bread is not ground. It is mechanically shredded using specialized blades that pull the loaf apart along its air-cell structure. This is how the distinctive needle-like shape is formed.

At this stage, texture is prioritized over taste. The resulting crumbs are intentionally dry, hollow, and lightweight, allowing them to:

- Absorb less oil during frying

- Create louder, longer-lasting crunch

- Maintain appearance after freezing and reheating 🔊🍤

Step 5: Dehydration and Stabilization

The crumbs are then dried at low temperatures to achieve precise moisture levels—often below what would occur in home kitchens. Anti-caking agents or flow enhancers may be added to improve packaging and transport performance.

Flavor is usually minimal. In many cases, salt and aroma compounds are added later by food manufacturers using the crumbs as an ingredient.

What Consumers Are Not Told

While needle-shaped breadcrumbs are not inherently unsafe, their marketing often implies simplicity and tradition, which does not reflect reality. Key facts often omitted include:

- Heavy reliance on refined ingredients

- Loss of natural fermentation benefits

- Use of processing aids and additives

- Design focused on industrial efficiency, not nutrition

In essence, needle-shaped breadcrumbs are functional food components, not artisanal bread derivatives.

The popularity of needle-shaped breadcrumbs is built on performance, not transparency. Their crunch, appearance, and stability are the result of precise engineering rather than traditional baking craft. Understanding this process allows consumers and professionals alike to make more informed choices about what they eat—and what they serve.

Sometimes, the crispiest products have the most complicated stories hidden beneath the surface 🧩🥖.