In the fish feed manufacturing process, drying is the critical, yet often overlooked, stage that transforms soft, vulnerable pellets into stable, shelf-ready products. fish food pellet making machine It is a precise balance of heat, airflow, and time—a delicate operation where science meets industrial efficiency to ensure nutritional integrity and longevity.

The Critical Role of Drying

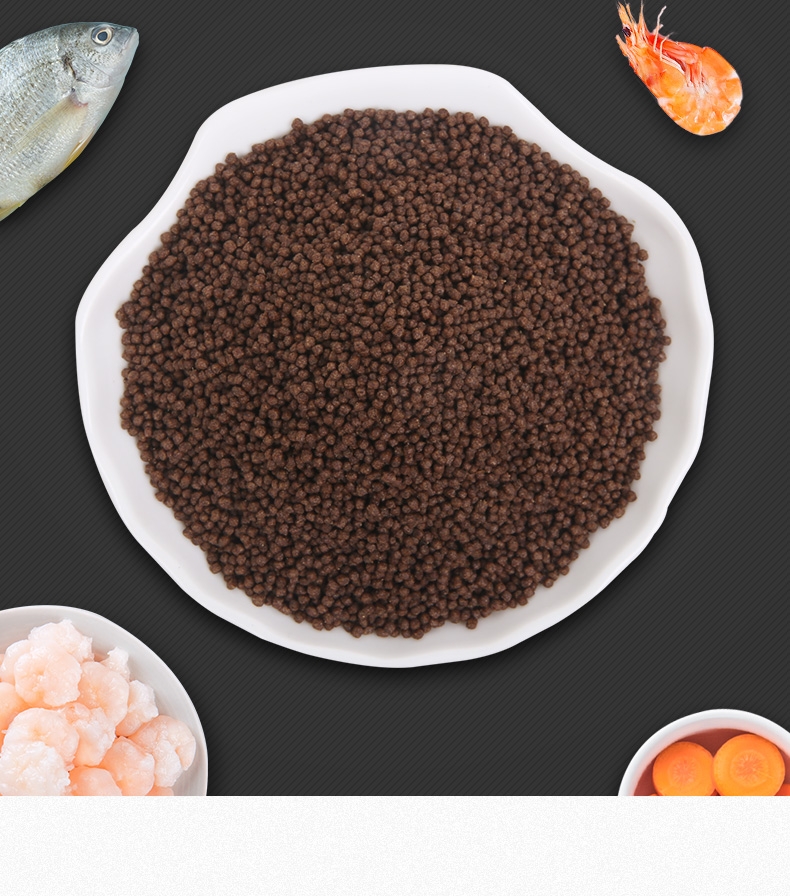

Freshly extruded (for floating feed) or pelleted (for sinking feed) pellets emerge hot and moist, with a moisture content of 23-30%. fish food pellet making machine This high moisture level makes them perfect breeding grounds for mold and bacteria, prone to clumping, and too soft for packaging and transport. The dryer’s mission is to rapidly and uniformly reduce this moisture to a safe 8-10%, creating a hard, stable, and microbiologically safe product.

The Heart of the System: The Multi-Pass Dryer

The industry standard is the multi-pass, continuous flow dryer. Imagine a large, insulated cabinet-like structure with a series of conveyor belts stacked on top of each other.

- Gentle Loading: The wet, warm pellets from the extruder or pellet mill are evenly distributed onto the top conveyor belt (the first “pass”).

- Cascading Flow: As the belt moves, the pellets travel to its end and then gently tumble down through controlled drop chutes onto the belt directly below, which moves in the opposite direction. This cascade repeats over 3 to 5 levels.

- The Counter-Current Principle: This is the key to efficiency. Hot, dry air (typically 90-120°C / 194-248°F) is blown into the bottom of the dryer. fish food pellet making machine It flows upward, opposite the direction of the pellets moving downward.

- Why? The driest pellets (now at the bottom) meet the hottest, driest air, ensuring final moisture removal without overheating. The wettest pellets (at the top) meet warm, humid air that has already picked up moisture from below. This prevents case-hardening—a phenomenon where the pellet’s outer shell dries too quickly, trapping moisture inside and leading to spoilage.

- Precise Control: The entire process is governed by programmable logic controllers (PLCs) that constantly monitor and adjust:

- Inlet Air Temperature

- Exhaust Air Humidity & Temperature

- Belt Speed (controlling retention time, usually 15-30 minutes)

- Airflow Volume and Velocity

The Science of Moisture Removal

Drying is not simply baking; it’s a two-stage mass transfer process:

- Constant Rate Period: Initially, free surface moisture evaporates quickly. The pellet surface remains cool due to the latent heat of vaporization, much like human sweat cools the skin.

- Falling Rate Period: As surface moisture is removed, internal moisture must migrate to the surface. This stage is slower and is carefully managed by controlling temperature and humidity to avoid damaging the pellet’s structure or its heat-sensitive nutrients.

Special Considerations for Feed Type

- Floating Feed: Requires meticulous control. The porous, expanded structure is fragile. Too hot or fast, and pellets can crack or become overly brittle, fish food pellet making machine increasing “fines” (dust). The goal is to preserve the air-cell structure that provides buoyancy.

- Sinking Feed: Tends to be denser and more robust, allowing for slightly higher temperatures or shorter times. The primary concern is achieving uniform core dryness.

After Drying: The Vital Cooling Step

Hot pellets exiting the dryer are not yet ready for storage; they must be cooled. A dedicated cooler, often a vertical column with ambient or slightly cooled air blowing through it, reduces the pellet temperature to within 5°C of the ambient air temperature. This prevents condensation inside storage bags, which would instantly re-introduce moisture and ruin the product.

Innovation and Efficiency

Modern drying focuses on energy recovery and precision.

- Heat Recovery Systems: Capture waste heat from the dryer’s exhaust to pre-heat incoming fresh air, dramatically reducing fuel (gas, oil) or steam consumption.

- Real-Time Moisture Sensors: Advanced near-infrared (NIR) sensors at the dryer outlet provide instant moisture readings, allowing for automatic, real-time adjustments to the drying parameters.

The dryer is the unsung hero of the fish feed mill. It is where the product gains its physical resilience and microbial stability. fish food pellet making machine This controlled application of thermodynamics—orchestrating heat, air, and movement—transforms a soft, perishable mass into a durable, nutritious, and consistent commodity. Without this precise and vital step, the sophisticated nutrition encapsulated in each pellet would be lost to spoilage long before it ever reached the water’s edge.