That perfectly uniform, sinking or floating pellet you sprinkle into your aquarium or that is dispensed by the ton into salmon pens is not a simple dried nugget of ground-up fish. fish food machine automatic It is the result of sophisticated food engineering, a process designed to balance nutrition, water stability, and manufacturing efficiency. Let’s pull back the curtain on the factory floor to see how fish feed gets its shape.

Stage 1: The Raw Powder Blend – The “Dry Mix”

It all begins with a homogenous powder. This mix is a precise recipe formulated by aquaculture nutritionists and can include:

- Sources de protéines : Fishmeal, soybean meal, poultry by-product meal, corn gluten, insect meal.

- Energy Sources: Wheat flour, cornstarch, other grains.

- Binders: Crucial ingredients like wheat gluten, which acts as a natural “glue.”

- Micronutrients: A precise premix of vitamins, minerals, and amino acids.

This dry blend is thoroughly mixed in giant industrial hoppers to ensure every single pellet will have the exact same nutritional profile.

Stage 2: The Conditioning Chamber – Adding Steam and Hydration

The dry mix is then fed into a conditioner. Here, it is exposed to live steam and sometimes hot water. This step is critical:

- It hydrates the starch and protein components.

- It begins the gélatinisation of starch—a process where starch granules swell and absorb water, becoming sticky and viscous. fish food machine automatic This natural starch gel will become the primary internal binder.

- It heats the mixture, typically to 80-95°C (176-203°F), making it pliable for the next, most dramatic stage.

Stage 3: The Heart of the Process – The Extruder

This is where the magic of shaping happens. The conditioned mash is forced into the extrudeuse, a barrel containing a rotating screw(s).

- As the material is pushed forward under immense pressure and friction, it cooks further. Temperatures can soar to 120-150°C (248-302°F).

- The screw compresses the mash against a metal plate at the end of the barrel—the mourir. The die has rows of precisely sized holes.

- Under this intense heat and pressure, the superheated, plasticized dough is forced through the die holes. As it exits into the cooler air at atmospheric pressure, the sudden pressure drop causes the trapped superheated moisture to flash into steam.

- This results in expansion—like popcorn or puffed breakfast cereal. The degree of expansion is carefully controlled by recipe, moisture, and temperature.

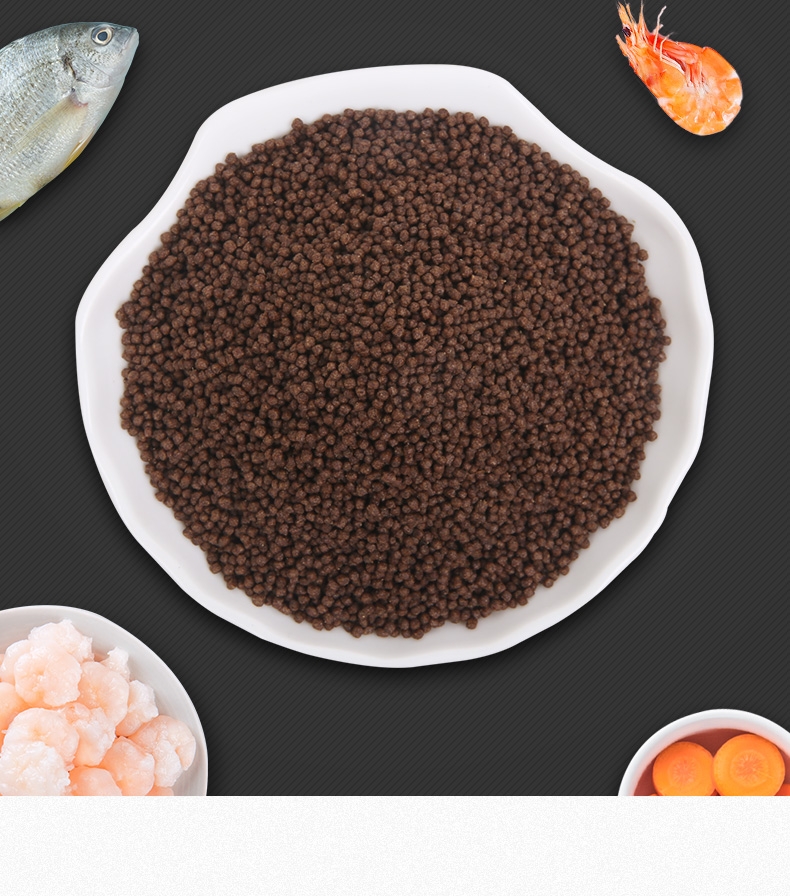

The result: Long, fluffy, low-density ropes of puffed feed. The die hole size directly dictates the final pellet diameter.

Stage 4: The Cutter and Dryer – Sizing and Stabilizing

Immediately upon exiting the die, fish food machine automatic a high-speed rotating knife slices the expanding ropes into precise lengths, creating the individual pellets.

- These soft, moist, and hot pellets are then conveyed into a massive multi-pass dryer.

- Here, forced hot air (typically 90-110°C / 194-230°F) circulates for up to several hours, slowly reducing the moisture content from ~25-30% down to a stable ~10%.

- Drying is vital for shelf stability, preventing mold, and ensuring the pellet is hard enough to survive handling and transport.

Stage 5: The Vital Coating – Adding Fats and Sensitive Nutrients

After drying, the pellets are hard and porous. This is when the most valuable and sensitive ingredients are added.

- The pellets are tumbled in a large, rotating vacuum or atmospheric coater.

- Liquid fats (fish oil, vegetable oils, phospholipids) are sprayed under pressure onto the tumbling pellets. The porous, sponge-like structure readily soaks up these oils. This coating significantly boosts energy density and palatability.

- Heat-sensitive additives that would have been destroyed during extrusion—such as certain vitamins, probiotics, enzymes, and medications—are applied in a protective lipid layer during this coating phase.

Stage 6: Cooling and Screening

Finally, the oil-coated pellets are cooled to just above room temperature to prevent caking during storage. They pass over vibrating screens to remove any fines (dust and broken pieces), which are recycled back into the process. The finished pellets are then ready for bagging.

The Engineering Choice: Sinking vs. Floating

- Floating Pellets: Achieved through high expansion during extrusion, creating a porous, air-trapping structure that is less dense than water.

- Sinking Pellets: Created by using a denser recipe, less steam in conditioning, a different die design, or by mechanically compressing the extruded pellet to reduce air pockets.

From a bland powder to a nutrient-dense, water-stable engineered sphere, the pelletizing process is what makes modern, intensive aquaculture possible. fish food machine automatic It encapsulates science, nutrition, and mechanical engineering into every tiny bite that farmed fish consume.