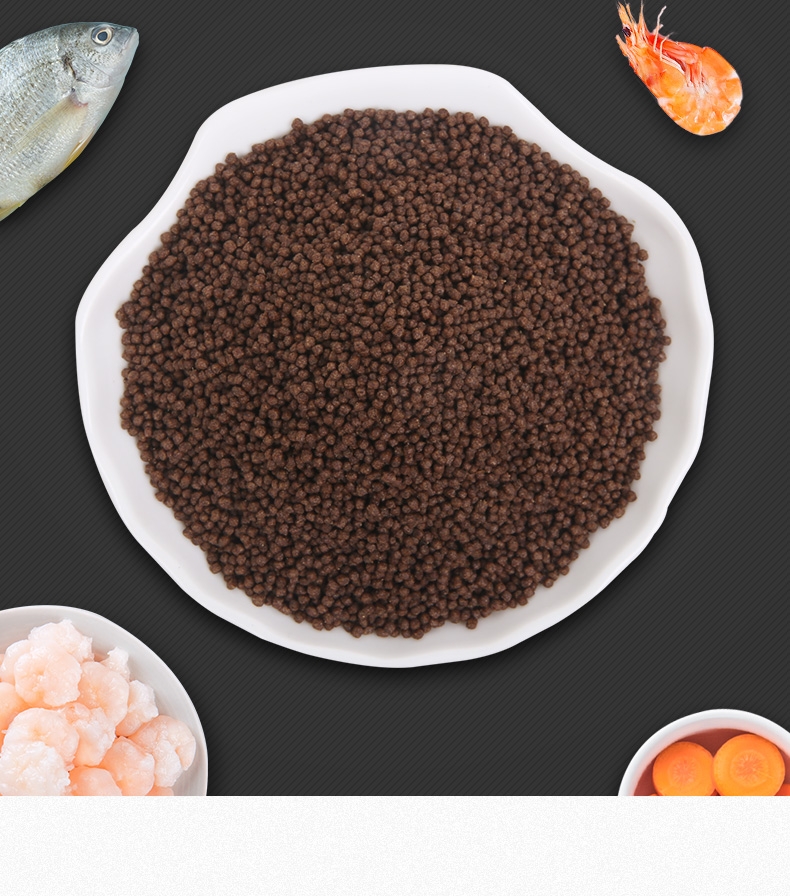

While floating pellets dominate the surface, a parallel universe of nutrition exists below—the world of sinking fish feed. fish food manufacturing machines These dense, compact pellets are engineered to descend, catering to the fundamental needs of a vast array of aquatic species. More than just an alternative, they represent a critical, species-specific feeding strategy grounded in biology and precision.

The Core Engineering: Density by Design

Unlike their buoyant counterparts, sinking pellets are manufactured to be denser than water. This is primarily achieved through one of two methods:

- Steam Pelleting (Compression): The most common method. The mash of ingredients is conditioned with steam but then forced through a die under high mechanical pressure using a pellet mill. This process creates significant friction and heat (typically 70-85°C), but without the dramatic expansion of extrusion. fish food manufacturing machines The resulting pellets are compact, hard, and have a low air content, causing them to sink immediately.

- Low-Expansion Extrusion: Using an extruder with modified parameters (less steam, higher dough density, different die design) to minimize air-pocket formation, producing a semi-sinking or slow-sinking pellet.

Key Characteristics & Biological Advantages

- Species-Specific Necessity: This is the paramount reason for their existence. Sinking feed is non-negotiable for benthic (bottom-dwelling) and demersal species whose natural feeding ecology is oriented downward. This includes:

- Marine Fish: Shrimp, prawns, lobster, crab, many marine finfish like halibut and grouper.

- Freshwater Fish: Catfish (in pond culture), sturgeon, loaches, and many ornamental species like cichlids and Corydoras catfish.

- It reduces physiological stress by aligning with innate foraging behavior.

- Reduced Nutrient Leaching & Water Stability: Sinking pellets, especially those made via steam pelleting, are often exceptionally hard and durable. They have lower porosity, which means they leach water-soluble vitamins and minerals more slowly as they descend. This ensures more nutrients are delivered intact to the fish, particularly important in pond systems or raceways with longer water column contact time.

- High Energy Density: The compact nature allows for a higher concentration of nutrients per pellet volume. They can effectively carry more fat (often from incorporated fish oil or lipids) without becoming unstable, which is crucial for high-energy diets for species like salmon smolts or marine shrimp.

- Lower Dust (Fines) and Waste: The pelleting process typically produces pellets with a smooth, hard surface that generates less powder or fine particles during handling and transport, leading to cleaner feeding and less clogging in automated systems.

The Formulation Profile

Sinking feed formulations are tailored to the target species but share common traits:

- Protein-Rich: Often higher in fishmeal or other premium protein sources for carnivorous and omnivorous bottom-feeders.

- Binding Agents: Critical for water stability. fish food manufacturing machines Common binders include wheat gluten, gelatin, guar gum, and specialized lignosulfonates. A stable pellet must remain intact long enough for slow-feeding species like shrimp to consume it.

- Fat Integration: Fats are usually incorporated internally into the mash before pelleting, rather than solely coated on the surface, to prevent rapid leaching.

- Attractants: Given the lower visibility in the water column, potent feeding stimulants (like krill meal, squid meal, or amino acid blends) are often essential to guide fish to the feed.

Considerations and Challenges

- Monitoring Difficulty: The greatest disadvantage is the inability to directly observe feeding activity. Uneaten feed settles out of sight, making it harder to adjust rations and creating a risk of overfeeding and bottom pollution.

- Water Quality Risk: If overfed, decomposing feed at the bottom can deplete oxygen and produce toxic metabolites like ammonia and hydrogen sulfide, especially in ponds without adequate water exchange or aeration.

- Species Restriction: It is entirely inappropriate for obligate surface feeders.

Application and Innovation

Sinking feed is the backbone of key aquaculture sectors:

- Shrimp Farming: Almost exclusively uses sinking feeds, with stability times (how long a pellet holds together) being a critical quality metric.

- Pond Culture of Catfish and Tilapia: Often fed using automated blowers that scatter pellets over a wide area.

- Hatcheries and Larval Feeds: Micro-pellets (crumbles) for early life stages are almost always sinking.

Innovation focuses on slow-sinking feeds for mid-water column feeders and functional feeds that deliver probiotics or medicines in a stable, sinking matrix.

Sinking fish feed is not a mere alternative but a fundamental technological adaptation to aquatic biology. It is a testament to the principle that successful aquaculture requires feeding fish the way they eat, not just what they eat. It represents a commitment to welfare, efficiency, and ecological realism—delivering precise nutrition into the depths where so much of aquatic life truly lives and feeds.