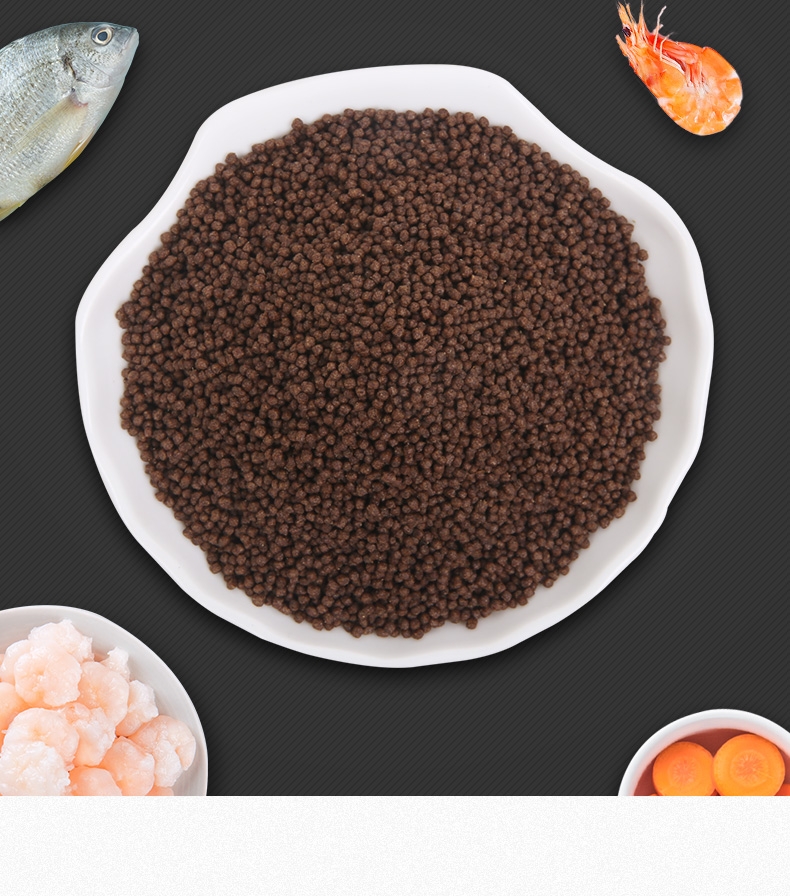

Sinking fish feed is a critical component in aquaculture, specifically designed for bottom-feeding species such as shrimp, catfish, certain carp, and marine finfish. fish feed extruder Unlike floating feed, which relies on high expansion, sinking feed requires a denser, more compact structure to ensure it reaches the desired depth quickly and maintains integrity in water. The manufacturing process, primarily using twin-screw extrusion, involves precise control of raw materials, mechanics, and thermodynamics.

1. Raw Material Selection and Formulation

The foundation of high-quality sinking feed lies in its formulation. Key considerations include:

- Protein and Lipid Sources: Fishmeal, soybean meal, poultry by-product meal, and selected oils (fish oil, vegetable oils). The ratio of protein to fat influences pellet density and water stability.

- Binders and Starch Sources: Wheat flour, wheat gluten, fish feed extruder and cassava starch are essential for binding and water stability. However, starch gelatinization is carefully controlled to limit expansion.

- Micronutrients: Vitamins, minerals, and attractants are incorporated, with attention to thermal stability during processing.

- Particle Size: Ingredients are finely ground (often below 200 microns) to ensure uniformity, enhance binding, and improve digestibility.

2. Conditioning and Pre-Mixing

- Dry ingredients are blended in a batch mixer to achieve homogeneity.

- Steam and water are added in a preconditioner to partially gelatinize starch and increase moisture content to approximately 22–28%. This step plasticizes the mixture, preparing it for extrusion but with controlled hydration to limit over-expansion.

3. Extrusion: The Core of Sinking Feed Production

The extrusion process for sinking feed is distinct from that of floating feed. fish feed extruder The goal is minimal expansion and high density.

- Twin-Screw Extruder Configuration: Screw elements are arranged to provide moderate shear and controlled pressure build-up. The design prioritizes mixing and cooking over rapid expansion.

- Temperature and Pressure Control: Barrel temperatures are typically maintained between 90°C and 130°C, with die-head pressures of 20–40 bar. These parameters are lower than those for floating feed to limit starch puffing.

- Moisture Management: Higher moisture content in the extruder barrel reduces viscosity and limits expansion. The dough remains more fluid, resulting in a denser product.

- Die Design: Sinking feed dies have shorter land lengths and may include cooling zones to reduce expansion at the point of exit. Pellet diameter is determined by die hole size, and cutter speed controls length.

4. Post-Extrusion Processing: Drying and Cooling

- Drying: Extruded pellets have a moisture content of 25–30% and must be dried to 8–10% for stability. Multi-stage belt dryers are used with carefully controlled air temperature (80–110°C inlet) and humidity to avoid case-hardening. The drying process is gradual to ensure uniform moisture reduction without creating internal cracks.

- Cooling: After drying, pellets are cooled to near ambient temperature using vertical or horizontal coolers. This step prevents condensation in packaging and stabilizes the pellet structure.

5. Fat Coating and Additive Application

- Sinking feeds often require high lipid levels for energy density. Since fats can reduce pellet stability, post-extrusion coating is critical.

- Vacuum Coating: The most effective method for sinking feed. Cooled pellets are transferred to a vacuum chamber, where air is removed from the pores. Liquid fat (fish or vegetable oil) is then introduced, penetrating deeply into the pellet core. This allows for high fat inclusion (up to 25–35%) without compromising water stability.

- Atmospheric Coating: Used for lower fat levels or heat-sensitive additives (vitamins, enzymes, pigments). A rotating drum applies a fine mist of oil and powders to the pellet surface.

6. Quality Control and Performance Metrics

- Sinking Rate: Measured in a water column to ensure pellets sink at the desired speed (typically ≥ 5 cm/sec). Controlled by density (1.1–1.4 g/cm³).

- Water Stability: Critical for slow-feeding species. Pellets are immersed in water for specified periods (e.g., 30 minutes to 2 hours) and assessed for disintegration. Stability is enhanced by binders and proper extrusion.

- Pellet Durability Index (PDI): Measures resistance to breakage during handling and transport. Sinking feed typically targets a PDI > 95%.

- Nutritional Integrity: Regular lab analysis ensures protein, fat, and micronutrient levels meet specifications, with attention to heat-sensitive nutrient retention.

7. Packaging and Storage

- Finished pellets are packaged in multi-layer, moisture-proof bags or stored in silos.

- Storage conditions must be cool and dry to prevent mold growth and nutrient degradation, especially given the high fat content.

Conclusion

Manufacturing sinking fish feed is a nuanced balance of formulation, fish feed extruder mechanical engineering, and process control. By carefully limiting starch expansion during extrusion, optimizing drying protocols, and employing advanced fat-coating technologies, producers can create dense, water-stable pellets that meet the ecological and nutritional needs of bottom-feeding aquatic species. The effectiveness of the final product depends on relentless attention to detail at every stage—from ingredient selection to post-processing—ensuring optimal growth, health, and environmental sustainability in modern aquaculture.