Floating vs. Sinking Fish Feed: A Comprehensive Guide

The choice between floating (extruded) and sinking (pelleted) fish feed is a critical decision in aquaculture and ornamental fish keeping, impacting feed efficiency, water quality, and animal health. Each type possesses distinct physical properties, manufacturing processes, and applications.

1. Core Difference: Buoyancy & Manufacturing Process

The fundamental difference lies in density, which is dictated by the production method.

- Floating Feed (Extruded):

- Process: Ingredients are mixed, conditioned with steam, and then forced through an extruder under high pressure and temperature (120-150°C). As the hot paste exits the die into atmospheric pressure, it rapidly expands, trapping air bubbles inside. This creates a porous, low-density structure.

- Result: The feed pellet has a density lower than water, causing it to float for an extended period (often 12-24 hours).

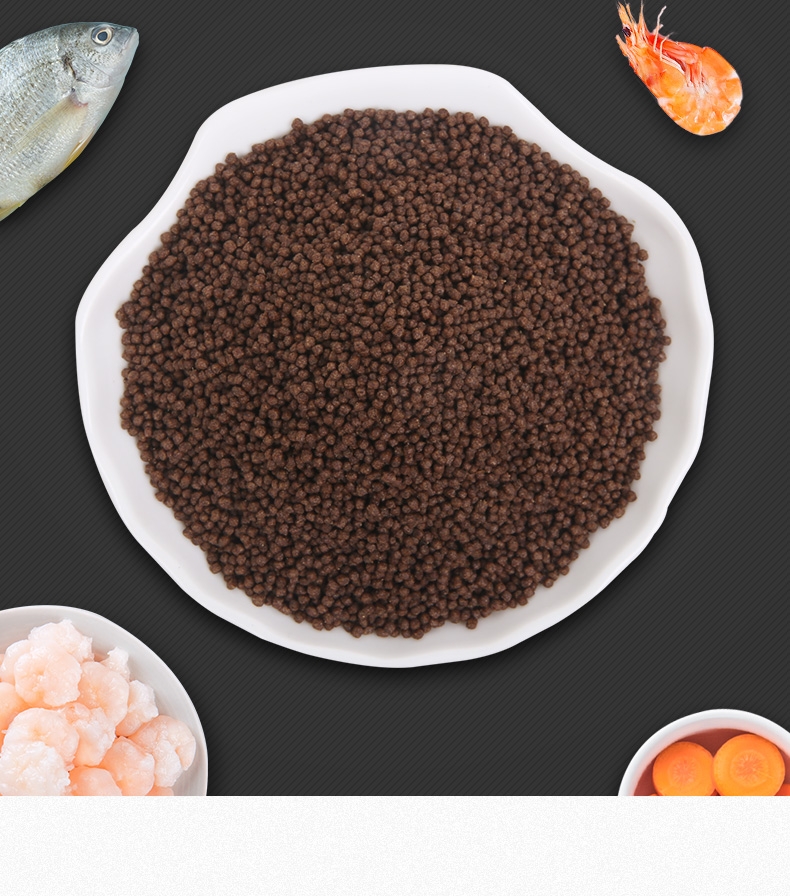

- Sinking Feed (Pressure-Pelleted):

- Process: Ingredients are mixed, conditioned with steam at lower temperatures, and then compacted through a mechanical pellet mill (die) under high pressure. The process involves less intense heat and no dramatic expansion.

- Result: The pellet is dense, with a density greater than water, causing it to sink immediately or shortly after contact.

2. Comparative Advantages & Disadvantages

| Feature | Floating Feed (Extruded) | Sinking Feed (Pelleted) |

|---|---|---|

| Feed Observation | Excellent. Allows direct observation of feeding activity, enabling farmers to adjust ration to appetite and minimize waste. | Poor. Feeding occurs below the surface, making it difficult to gauge consumption rates. |

| Water Quality | Generally Superior. Uneaten feed is visible and can be skimmed off. Less disintegration at the surface reduces immediate pollution. | Risk is higher. Uneaten feed sinks to the bottom, where it decomposes, directly releasing ammonia and compromising water quality. |

| Nutrient Stability | High. The high-temperature process gelatinizes starches thoroughly, improving digestibility. It also better destroys anti-nutritional factors and pathogens. | Moderate. Lower processing temperatures may preserve some heat-sensitive nutrients but can leave starches less digestible. |

| Energy Cost | Higher. The extrusion process is energy-intensive. | Lower. Pellet milling requires less energy and capital investment. |

| Durability & Stability | Very High. Hard, porous structure minimizes fines (dust), allows for oil coating, and maintains integrity in water longer. | Variable. Softer and can disintegrate faster in water if not properly bound, leading to nutrient leaching. |

| Target Species | Surface & Mid-water feeders: Catfish, Tilapia, Koi, Ornamental goldfish. | Bottom feeders: Shrimp, Prawns, Marine finfish (e.g., groupers, seabass), Eels. |

| Price | Typically more expensive due to processing costs. | Generally more economical. |

3. Key Application Scenarios

Choose Floating Feed When:

- Managing Stocking Density: For species like tilapia and catfish in ponds or cages, where direct feeding observation is crucial for health checks and waste management.

- Optimizing Feed Conversion Ratio (FCR): The ability to see and control uneaten feed directly improves FCR, a key economic metric.

- Feeding Fish with Accessory Breathing Organs: Species like catfish and labyrinth fish (e.g., bettas) that gulp air at the surface prefer floating feed.

- Ornamental Ponds: Koi and goldfish owners prefer it for interactive feeding and water quality maintenance.

Choose Sinking Feed When:

- Feeding Bottom Dwellers: It is essential for the natural feeding behavior of shrimp, prawns, loaches, and many marine species.

- Minimizing Air Ingestion: For some deep-bodied fish, consuming floating feed can lead to swim bladder disorders due to ingested air.

- Cost-Sensitive Operations: Where the capital and operational cost of extruders is prohibitive, and species biology allows for sinking feed.

4. The Science of Digestion & Formulation

The processing difference affects more than buoyancy:

- Starch Gelatinization: Extrusion’s high heat significantly increases starch gelatinization, improving carbohydrate digestibility for omnivorous fish like carp and tilapia.

- Fat Content: The porous structure of floating feed can be post-coated with high levels of fat/oil after extrusion, creating high-energy diets without compromising pellet stability. Sinking pellets must have fat incorporated internally before pelleting, which can limit total fat content.

- Sinking Speed: Modern technology allows for “slow-sink” feeds, which are extruded to have a near-neutral density. These are vital for mid-water column feeders like salmon and certain marine species.

Conclusion: A Decision Driven by Biology and Management

There is no universally “better” type. The choice is a strategic decision based on:

- Species-Specific Ethology: What is the natural feeding zone of the fish?

- Management Goals: Is optimizing FCR and observing stock the priority, or is minimizing upfront feed cost more critical?

- Production System: Is it a clear-water tank, an earthen pond, or a sea cage?

The modern trend is toward functional, specialized feeds—whether floating or sinking—that are tailored to the precise life stage, health need, and environment of the cultured species, with extrusion technology enabling more precise nutritional engineering. Understanding this fundamental buoyancy difference is the first step in effective and sustainable feeding.